As secondary objectives we can mention:

1. Determine the most appropriate procedure in the airification stage

2. Determine how airing affects the fermentation time.

Project Plan:

I will start by describing the stages of the fermentation process.

HARVEST:

The cocoa production cycle is the whole year, presenting two periods of increased production: from April to June and November to December.

The harvest begins when the ear is mature what happens in a period of 5 to 6 months of age. The cob presents change of pigmentation: from green to yellow or red and others similar to strong orange or pale yellow. On cobs of red coloration - very accentuated violaceous, the change of color may not be very apparent and there is a risk of not harvesting time the ears that have reached full maturity. Because this difficulty the ears can ripen and germinate. When doubts exist regarding the state of maturity of the ear, it is enough hit it with the fingers of the hand and if a hollow sound occurs It is a sign that it is mature.

Cocoa ready for harvest

Harvested ears should not be stored as there is the risk of the almonds germinating inside the ear.

The harvest should be done at regular intervals every two to three weeks In the presence of a strong incidence of diseases such as Moniliasis and Black Cob, the harvest is done at intervals less than time.

The tools used for the harvest are: scissors pruning, gavilana and stairs type "A". All cutting tools they must be well sharpened and disinfected.

The ears to be harvested are cut by the middle part of the peduncle that joins the fruit to the tree to avoid damaging the floral cushion.

The hawk is used to cut the peduncle by lowering the tool from top to bottom, never in the opposite direction because it would tear the floral cushion.

SHRED:

It consists in splitting the cob and extracting the almonds, which Once separated from the placenta, they will be subjected to fermentation.

The bankruptcy of the ears is done with conditioned tools especially for this work as short machetes or with pieces of wood to hit and open. Care must be taken of not damaging the almonds that remain attached to the placenta.

The separation of the grains is done by hand. The shelling is done immediately after breaking the cob. The time between shattering and fermentation

It must not exceed 24 hours.

When the harvest is done, several points are determined within of the plantation where the ears are piled up, they break, shells and then the almonds are transported in buckets or bags plastic to the fermenters.

shatter of cocoa

FERMENTATION:

Fermentation is a very important step to have a cocoa high quality, with aroma, flavor and color of chocolate.

Cocoa almonds are fermented in special containers, in protected and well-ventilated places, for a period from three to six days, depending on the type of cocoa and the area.

The almonds put to ferment are stirred or overturned each twenty-four hours from one drawer to another or within the same drawer, if the volume allows it, and until the almonds take a brown or chocolate color with incrustations or pronounced streaks.

During rest, the temperature rises and becomes stable in 45 ° C. Poor fermentation causes a violet color or whitish that is observed when splitting the almonds in half.

Fermented cocoa seed

With the death of the embryo there is a greater permeability of cell walls and a production of cellular juices. This the enzymes are contacted with the polyphenols and the proteins, initiating then a process of hydrolysis.

This process is responsible for the change of the characteristic flavor of chocolate, transforming the protein into amino acids. In this The hydrolysis of polyphenols occurs by enzymes.

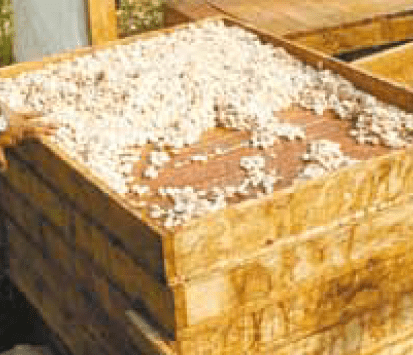

Box fermentation method:

Wooden crates with perforations in the bottom are used to the runoff of the juices. They can be placed in unevenness (type ladder) to facilitate turning. The size of the boxes depends of the volume of production to put to ferment.

Box to ferment cocoa

It is another simple method, easy to operate, cheap and ideal for small and medium producers, are made of wood with dimensions of 1.2 m long, 0.8 m wide and 0.12 m deep, one envelope is placed another, in the amount of ten to fifteen boxes. Almonds are obtained well fermented.

Rohan Box

DRYING COCOA:

It is the process in which the grain loses moisture until take it to 6%, which is left ready for the market and / or for store it.

This process can be done in the sun or artificially.

Sun dried:

It is the most used form and that ensures a good quality of cocoa, what is achieved between 6 and 8 days of sun. It is done by putting cocoa in thin layers on a wooden platform or mat bamboo that are materials that do not transmit flavors or smells strangers. The method of sliding wooden drawers, with ceiling

Fixed or mobile is the most effective. Its use depends on the capacity economic of the producer.

Drying of cocoa in the sun

Then we will organize the development of the project in four stages:

Fermentation box design